Optimizing Space: The Secret to Minimalist Warehousing

Understanding Minimalist Warehousing

In today's fast-paced business landscape, warehouses are not just storage spaces but strategic assets that can significantly influence a company's efficiency and profitability. Embracing a minimalist approach to warehousing can lead to optimized space utilization, reduced costs, and improved productivity. By focusing on essential items and eliminating unnecessary clutter, companies can transform their warehouses into lean, efficient operations.

Minimalist warehousing is not about having less; it's about making the most of what you have. This requires careful planning, smart inventory management, and innovative storage solutions. The goal is to create a streamlined environment where every square foot is used effectively.

Benefits of Space Optimization

Optimizing warehouse space offers numerous benefits. Firstly, it increases the storage capacity within the existing footprint, postponing or eliminating the need for costly expansions. Secondly, it enhances operational efficiency by reducing the time needed to locate and retrieve items. This ultimately boosts productivity and lowers labor costs.

Moreover, a well-organized warehouse improves safety by reducing the risk of accidents caused by clutter. It also enhances the accuracy of inventory management, minimizing errors and improving customer satisfaction. These factors combined can provide a competitive edge in the market.

Implementing Efficient Layouts

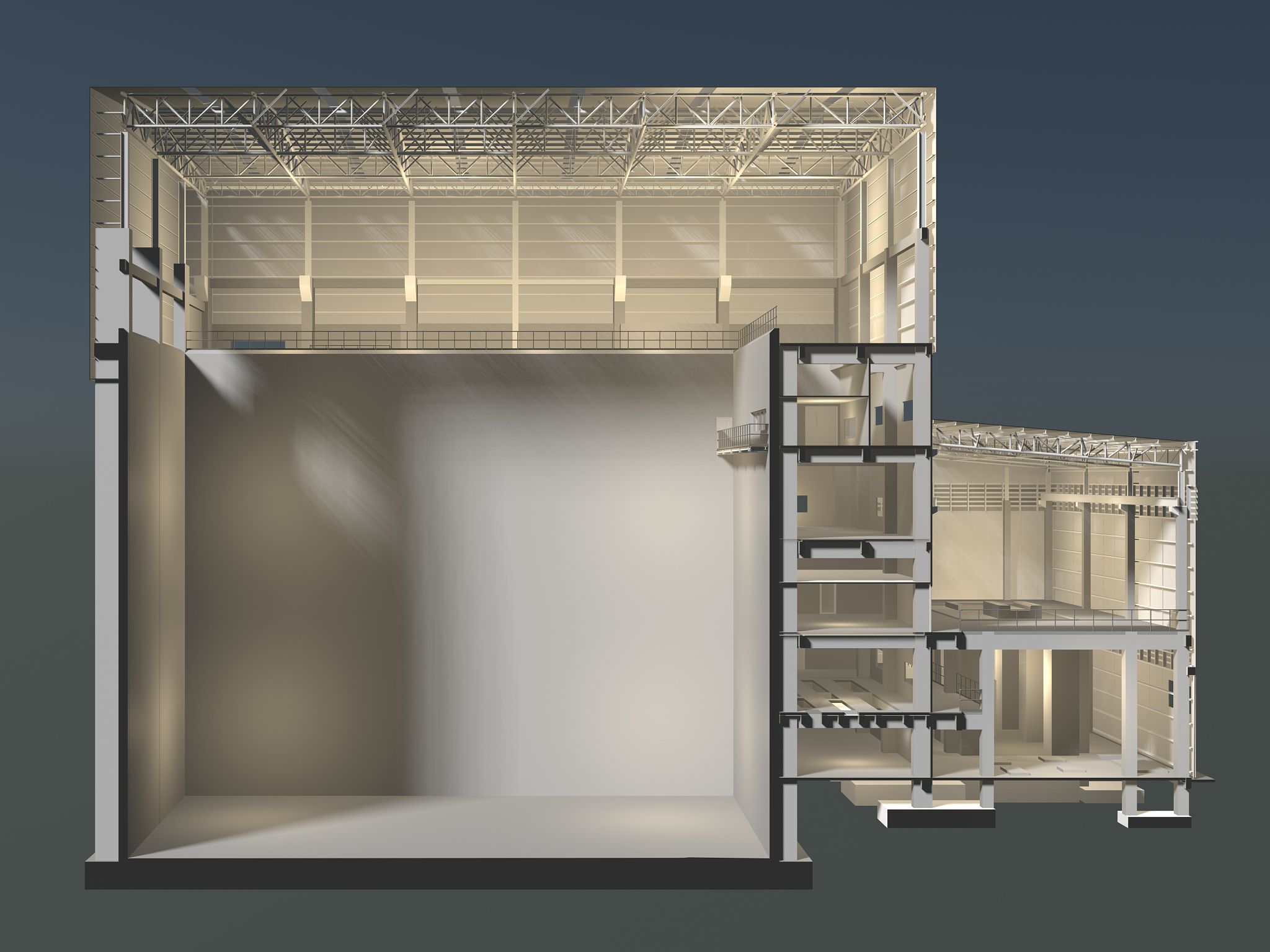

One of the first steps in optimizing warehouse space is to design an efficient layout. This involves analyzing the flow of goods and arranging aisles, racks, and workstations to support seamless operations. Considerations such as aisle width, storage equipment, and accessibility play a crucial role in maximizing space.

Utilizing vertical space is another critical aspect. Installing taller shelving units or mezzanines can significantly increase storage capacity without expanding the warehouse footprint. However, it's important to ensure these structures comply with safety regulations.

Inventory Management Techniques

Effective inventory management is essential for maintaining a minimalist warehouse. Techniques such as Just-In-Time (JIT) inventory can reduce excess stock and free up space for more critical items. JIT ensures that materials are received only as needed for production, minimizing inventory holding costs.

Additionally, implementing an automated inventory tracking system can provide real-time visibility into stock levels, reducing the likelihood of overstocking or stockouts. This technology-driven approach helps maintain optimal inventory levels and enhances overall warehouse efficiency.

Adopting Smart Storage Solutions

Smart storage solutions are key to optimizing space in a minimalist warehouse. Adjustable shelving systems, modular racks, and stackable containers allow for flexible storage configurations that can be adapted as business needs change. These solutions enable businesses to efficiently utilize every inch of available space.

Furthermore, incorporating automation technologies such as Automated Storage and Retrieval Systems (AS/RS) can improve space utilization by compactly storing items and swiftly retrieving them when needed. These systems reduce reliance on manual labor and enhance picking accuracy.

Conclusion

Optimizing space through minimalist warehousing is a strategic move that can yield significant benefits for businesses. By focusing on efficient layouts, advanced inventory management techniques, and smart storage solutions, companies can transform their warehouses into streamlined operations that support growth and profitability.

As businesses continue to seek ways to enhance efficiency and reduce costs, minimalist warehousing stands out as an effective approach to achieving these goals. Embracing this strategy not only maximizes space but also aligns with sustainability efforts by reducing waste and promoting resourceful use of materials.